Accessories & Parts

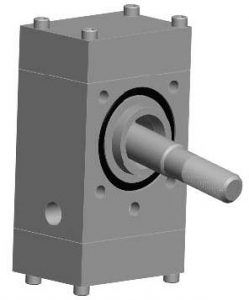

800 Interface Pilot Block

-

Used on all OCV filter separator float controls

-

Accurate and responsive movement to rising water

-

Low friction operation

-

Pressure balanced design

-

Resilient seating resists le akage

-

Four-way control to actuate discharge slug valve and/or automatic water drain valve

-

No lubrication necessary

-

Unique, time-proven design

-

Factory tested

-

All-Stainless Steel construction

The model 800 pilot block is the key control element of all OCV filter separator float controls, the sole purpose of which is to allow only the discharge of clean, water-free fuel from the filter separator.

PILOT BLOCK CONNECTIONS (All ports 1/8” NPT)

POWER: Filter separator vessel pressure

ACCELERATOR VALVE: Bonnet of accelerator pilot on discharge slug valve

WATER DRAIN: Bonnet of automatic water drain valve

EXHAUST: Atmospheric drain line

OPERATION

Equipped with the proper counterweight float, the float will “ride” the interface between water and fuel in the filter separator sump. Depending on the water level, the Model 800 will route filter separator pressure from the POWER port to the other components in the system as follows:

FLOAT DOWN: The accelerator pilot bonnet is pressurized, allowing the slug valve to open and discharge fuel. The water drain valve bonnet is vented, keeping it closed.

FLOAT IN MEDIAN POSITION: Both the accelerator and water drain valve bonnets are pressurized. The slug valve remains open and discharging fuel, while the water drain valve opens and begins discharging accumulated water.

FLOAT UP: The accelerator bonnet is now vented, causing the slug valve to close. The bonnet of the water drain valve remains pressurized, and water continues to be discharged.

MATERIALS

Body, end caps, internals: Stainless Steel

Seals: Viton®

Seal repair kit: P/N 920010

MAXIMUM PRESSURE: 300 PSI (20.7 bar)

OPERATING TEMPERATURE: 32°-120°F (0°-49°C)

The 800 pilot is used on four different float assemblies, as shown below. For details on these models, refer to the individual model sheets.

| MODEL | DESCRIPTION |

| 800B | Bottom-mount / 7.5” dia. Flange |

| 800C | Side-mount / 4” Victaulic connection |

| 800D | Side-mount / 8” dia. Flange |

| 800H | Bottom-mount / 10” dia. Flange / Low-profile float |